No products in the basket.

Tough Decking – Frequently Asked Questions

Our Frequently Asked Questions page is designed to help you find answers to the most common questions regarding the purchase, installation, and ongoing maintenance of Composite Decking.

Although we try to answer every question asked of us, there may be times when your particular installation is far more complicated. In this instance, if you can’t find the answers to your questions here, we advise that you give us a call during office hours to discuss your project.

Filter FAQ’s Categories

Planning & General QuestionsInstallation & MaintenanceWarranty & After Sales SupportShow AllInstallation & Maintenance (12)

As a general rule we expect you to have your order within 3-4 working days. We offer one of the fastest delivery schedules for composite decking in the UK.

Remote locations such as the Scottish Highlands, Channel Islands etc. will experience a longer delivery schedule.

Decking Fall refers to the slight slope or angle that is intentionally created in the surface of the deck. This slope is usually achieved by sloping the deck’s substructure, or by using special joists or other supports designed to create a sloped surface.

The reason for creating a decking fall is to ensure that the surface of the deck is not completely flat, but instead has a slight slope that allows water to drain off of it. This is important because if water is allowed to pool on the surface of the deck, it can cause damage to the decking material over time, and can also create a slip hazard when the surface is wet.

By creating a slight slope in the surface of the deck, water is directed towards the edges of the deck where it can be safely drained away. This helps to protect the decking material and ensure that the deck remains safe and functional for years to come.

Supporting the ends of composite decking boards is important for several reasons.

Firstly, composite decking boards can expand and contract with changes in temperature and humidity. This movement can be more pronounced at the ends of the boards. If the ends are not properly supported, they can sag or even break, causing an uneven and unstable surface.

Secondly, composite decking boards are typically heavier than traditional wood boards. This extra weight can put additional stress on the ends of the boards, making them more susceptible to damage if not properly supported.

Finally, supporting the ends of composite decking boards helps to ensure a more uniform and attractive appearance. Without proper support, the ends of the boards may bow or warp, leading to an unsightly and unprofessional finish.

We recommended using 8 fixing clips per board for several reasons.

- Stability: Using 8 fixing clips per board ensures that the board is securely fastened to the joists, which improves the overall stability and durability of the deck.

- Even spacing: Using 8 clips per board also ensures that the board is evenly spaced from the adjacent boards, which creates a consistent and aesthetically pleasing appearance.

- Reduced movement: Composite decking boards tend to expand and contract with temperature changes, and using 8 fixing clips per board helps to reduce the movement and minimize the risk of warping or buckling.

- Better weight distribution: Distributing the weight of the board across 8 clips instead of just a few helps to prevent the board from sagging or bending under heavy loads, which is important for maintaining the integrity of the deck.

Overall, using 8 fixing clips per board is a best practice for installing composite decking, and it helps to ensure a long-lasting, stable, and visually appealing deck.

If you have forgotten to install a double joist in the context of composite decking, there are several options available to you.

- Install a sister joist: If the existing joist is still in good condition, you can install a sister joist next to it. A sister joist is a second joist that is attached to the existing joist, which can help to provide additional support for the decking board.

- Add blocking: If you cannot install a sister joist, you can add blocking between the existing joists. Blocking is a piece of wood that is installed between the joists, which can help to prevent the decking board from sagging or bending.

- Replace the board: If the decking board is already installed, you may need to remove it and install a new board with the correct support. While this may be more time-consuming, it is important to ensure that the deck is structurally sound and safe.

A “Noggin” is a term used to refer to a piece of material, usually made of wood, that is used to provide structural support between joists or to fill in gaps between them. Noggins are often used to prevent the joists from twisting or bending, and to improve the overall stability of the deck. They are typically installed perpendicular to the joists and secured in place with screws or nails.

Cleaning composite decking is a relatively simple process that can be done using basic tools and materials. Here are some steps to follow:

- Clear the surface: Remove any debris, leaves, or twigs from the surface of the decking using a broom or a leaf blower.

- Apply the cleaning solution: Apply the cleaning solution using a soft-bristled brush or a power washer on a low setting, working in small sections at a time. Avoid using a pressure washer on a high setting, as it may damage the surface of the decking.

- Scrub the surface: Use a soft-bristled brush to scrub the surface of the decking in a circular motion, focusing on any areas with stains or dirt buildup.

- Rinse the surface: Rinse the surface thoroughly with clean water using a hose or pressure washer on a low setting to remove all the soap residue and dirt.

- Let it dry: Allow the decking to dry completely before using it again.

We have a page dedicated to Composite Decking Cleaning with an in depth explanation, and video showing you the cleaning steps.

If you have scratched your composite decking, it may not be necessary to replace it. Composite decking is durable and can withstand minor scratches and scuffs. However, the severity of the scratch will determine if you need to replace the affected boards.

If the scratch is minor and doesn’t affect the structural integrity of the board, you can consider repairing the scratch. You can use a heat gun or a hot air blower to heat the scratch, which will cause the composite material to expand and fill in the scratch.

If the scratch is deep and affects the structural integrity of the board, you may need to replace the affected boards. Deep scratches can compromise the strength and stability of the board, which can affect the safety of the deck.

The severity of the scratch will determine if you need to replace your composite decking. If the scratch is minor, you can repair it. If the scratch is deep and affects the structural integrity of the board, you may need to replace the affected boards.

Expansion and contraction should be factored in when installing composite decking because the material can expand and contract with changes in temperature and humidity. Composite decking is made of a combination of wood fibres and plastic, which can react differently to environmental changes.

During hot weather, the composite decking can expand, and during cold weather, it can contract. If the decking is not installed with enough space for this expansion and contraction, it can cause the boards to buckle, warp, or crack. This can lead to an unsightly and unsafe deck surface.

To prevent these issues, it’s essential to leave a gap between each board when installing composite decking. The amount of space needed will depend on the specific product being installed and the climate in the installation area.

By factoring in expansion and contraction during installation, you can ensure that your composite decking looks great and remains structurally sound for years to come.

An expansion gap refers to the space left between the ends of the decking boards to accommodate any potential expansion or contraction of the material due to changes in temperature and humidity.

A staggered joint refers to a method of joining two boards end-to-end in a way that creates a more visually appealing and structurally sound deck surface.

Instead of having all the seams between boards lined up in a straight line, a staggered joint involves offsetting the seams so that they are not directly aligned. This creates a more natural and random appearance that resembles the look of a traditional wood deck.

Staggering the joints also helps to distribute the weight and stress on the deck more evenly, which can help to prevent warping and other forms of damage over time.

To fix Fascia Skirting or L Profile trim to your composite decking by Tough Decking, you can follow these steps.

- Start by cutting the fascia skirting or L profile trim to the correct length and width to fit around the perimeter of your deck.

- Use a chalk line or other straight edge to mark a line where the top of the fascia or trim will sit.

- Apply clear adhesive/sealant to the back of the fascia or trim, spreading it evenly over the surface.

- Align the fascia or trim with the chalk line and press it firmly into place against the edge of the decking.

- Use stainless steel screws to secure the fascia or trim to the decking. Make sure to pre-drill holes in the fascia or trim to prevent splitting, and use screws that are long enough to penetrate both the fascia and the underlying framing.

- Repeat the process for each section of fascia or trim until the entire perimeter of the deck is covered.

- Once all the fascia or trim is in place, use a saw or router to trim any excess material from the edges.

Planning & General Questions (10)

Composite decking is a type of decking material that is made from a combination of wood fibers or sawdust and plastic. Here are some benefits of composite decking:

- Low Maintenance: Composite decking requires very little maintenance compared to traditional wood decking. It does not need to be stained or sealed and can be cleaned with just soap and water.

- Durability: Composite decking is very durable and resistant to rot, mold, and insects. It can last for many years without the need for replacement.

- Environmentally Friendly: Composite decking is made from recycled materials, making it an eco-friendly option. It also does not require the use of chemicals for maintenance, reducing its impact on the environment.

- Variety: Composite decking comes in a wide range of colors, styles, and textures, making it easy to find a design that matches your preferences.

- Safety: Composite decking is slip-resistant and splinter-free, making it a safer option for families with children and pets.

- Value: While composite decking may have a higher upfront cost than traditional wood decking, it can provide long-term value by lasting longer and requiring less maintenance.

Yes, composite decking has several advantages over conventional wood decking. First, it is highly durable and resistant to rot, decay, and insect infestation. It also requires less maintenance, saving you time and money in the long run.

Second, composite decking comes in a wide range of colors and styles, allowing you to customize your deck to suit your personal taste and preferences. It also has a consistent appearance, with no knots or splinters that can detract from its beauty.

Third, composite decking is made from recycled materials, making it an environmentally friendly option that does not require the use of harmful chemicals for treatment. Finally, composite decking is slip-resistant, even when wet, making it a safer option than conventional wood decking.

Composite decking is typically installed using a combination of screws and hidden fasteners. Here’s a general overview of the installation process:

- Begin by ensuring that the substructure (the framing that supports the deck) is properly installed and level.

- Install a starter strip along the outer edge of the deck to ensure a straight, level surface for the first row of boards.

- Starting at the house, lay the first board with the groove facing toward the edge of the deck. Secure the board to the substructure using T-Clips and screws.

- Install the next board by inserting a T-Clip to the first board and then securing it to the substructure. Repeat this process for the remaining boards.

- Once all the boards are in place, trim the ends to fit the deck’s perimeter and install a finishing board along the outer edge.

- Finally, install any necessary trim pieces or railing systems.

To calculate the approximate number of decking boards required we take the area of each board (150mm width x 2200mm length) which works out to 0.33sqm per board.

Measure the length times the width of your proposed decking area and divide by 0.33.

For example: for a decking area measuring 4m x 5m the total area is 20 m2, if we divide this by 0.33 we get approx. 61 boards. As a general rule, we add 10% for cuts and mistakes, which would take this board total to around 67 decking boards.

Composite decking can be installed by a professional contractor or a skilled DIY homeowner who has experience with construction projects. It is important to follow our installation instructions carefully and use the appropriate tools and materials to ensure a safe and successful installation. In addition, local building codes and regulations should be considered when planning and executing the installation. If you are not experienced with construction projects, it is recommended to hire a professional contractor to install your composite decking.

Composite decking can be relatively easy to install, especially for those with some experience in construction projects. The installation process typically involves cutting the composite decking boards to size, securing them to a substructure or framing, and finishing the edges and corners. Composite decking often features specialised clips or fasteners that help to simplify the installation process and ensure a clean, professional-looking finish. However, the difficulty of installation may depend on the specific product, the complexity of the installation, and the experience and skill level of the installer. It’s important to carefully read and follow our installation instructions and safety guidelines to ensure a successful and safe installation.

A double joist is a type of framing that involves using two joists (horizontal support beams) instead of one to create a stronger and more stable substructure for composite decking. The double joist technique involves spacing the two joists closer together than standard spacing and placing them side by side. The composite decking boards are then secured to both joists, providing additional support and reducing the risk of sagging or warping over time.

The framework of a composite decking installation is important because it serves as the foundation for the entire structure. The substructure or framing provides the necessary support for the decking boards and ensures that they remain level and stable over time. In addition, the framing can help to prevent moisture damage, rot, and decay, which can compromise the structural integrity of the entire installation. Proper framing techniques, including the use of double joists where appropriate, can help to ensure a safe, durable, and long-lasting composite decking installation.

Commercial grade refers to a type of decking product that is designed and manufactured to meet the specific needs of commercial applications, such as parks, hotels, and other high-traffic areas. Commercial grade composite decking typically features a more durable and heavy-duty construction than residential grade decking, with higher load capacities and greater resistance to wear and tear.

Commercial grade composite decking may be made from higher quality materials, such as thicker boards or more advanced polymer composites, and may be subject to more rigorous testing and quality control standards than residential grade products. This can result in a higher price point for commercial grade composite decking, but also a longer lifespan and lower maintenance requirements over time, making it a cost-effective choice for commercial settings.

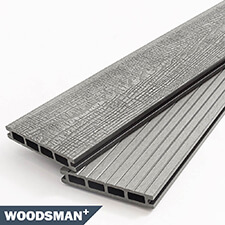

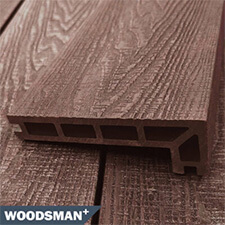

Uncapped and Capped refer to different types of composite decking products based on their construction and performance.

Uncapped composite decking is made of a composite material that is not covered with a protective coating or shell. This type of decking may be less expensive than capped decking, but it may be more prone to fading, staining, and moisture damage over time. Uncapped decking may also be more susceptible to scratches, mold growth, and other types of wear and tear, as the composite material is exposed to the elements.

Capped composite decking, on the other hand, features a protective outer layer or “cap” that is designed to enhance the durability and longevity of the decking. This cap may be made of a variety of materials, including polymer, PVC, or other synthetic materials, and is designed to resist fading, staining, and moisture damage. Capped composite decking may also be more resistant to scratches, mold, and other types of wear and tear, making it a popular choice for homeowners who want a low-maintenance, long-lasting decking option.

Overall, the choice between uncapped and capped composite decking may depend on factors such as budget, desired level of maintenance, and the specific performance needs of the decking installation.

Here at Tough Decking we pride ourselves on giving excellent customer service. To this end, if you need assistance in planning and designing your decking area please give us a call or send us an email and we will walk you through the steps, and if required provide a FREE no obligation quote.

Warranty & After Sales Support (4)

If your composite decking boards have moved on the joists, there are a few steps you can take to fix the problem:

- Identify the cause: First, try to identify the cause of the movement. It could be due to expansion and contraction caused by changes in temperature and moisture levels, or it could be due to improper installation.

- Check the joists: Make sure the joists are properly spaced and level. If they are not, adjust them as needed.

- Re-position the boards: Gently re-position the boards back into place, making sure they are properly seated on the joists.

- Secure the boards: Secure the boards to the joists using composite deck screws or hidden fasteners, making sure they are spaced properly to allow for expansion and contraction.

- Consider adding additional support: If the problem persists, consider adding additional support, such as blocking between the joists or adding extra joists.

Unwanted products can be returned for a full refund within 30 days from the date you took delivery.

Returned goods must be returned in their original unused condition.

Further details about our refund and returns process can be found here: Returns & Refunds

Because the decking is uniquely uncapped, minor scratches or dents caused by pets or heavy garden furniture can be easily sanded out with fine grade sandpaper.

If the boards do warp, splinter or break, then please contact our technical team at your earliest convenience.

When you receive your order invoice by email it will include a tracking link with parcel/consignment reference. If you click the link and enter your reference number you can track your delivery. Depending on the courier/carrier you maybe asked to enter your delivery postcode.

If you have signed up for a Tough Decking Account, you can also track your orders via the: www.toughdecking.co.uk/my-account/orders/ page. Just select the order you wish to track. If tracking has been provided it will appear at the top of the order.